Acceptable Quality Limit (AQL)

How to determine the quantity to be inspected?

While we all would like to have every single unit of goods to be inspected, this is simply not practicable or affordable for most products and companies.

The best approach, which is recommended by International Standards Agencies such as ANSI/ ASQ, is to use the AQL (Acceptable Quality Limit or Level) approach to determine both the sample inspection size and the levels required to determine of an Inspection is a Pass or a Fail.

We use the internationally recognized Acceptable Quality Limit (AQL) standard for all product inspections. For each inspection, this allows the client to set their acceptable quality tolerance levels.

What is AQL (Acceptable Quality Limit or Level)?

AQL is sometimes called Acceptable Quality Limit by some people or Acceptable Quality Level by others. They both essentially mean the same thing.

To determine the AQL level of a product you need to use the measure table that is recommended by ISO 2859, NF06-022, DIN 40080, BS 6001, ANSI/ASQC Z1.4.

This table allows you to determine the sample size (amount or quantity) that should be taken from an order or batch to be inspected or tested. It then provides you with the values to determine whether a product has met the buyers specifications and passes or fails the inspection.The customer then has the data to make an informed decision to accept or reject the lot.

You can then determine the tolerance levels in terms of Critical, Major and Minor levels for your product. The tolerance levels is a fair and equitable method which gives the seller and the buyer leeway to determine what is an Pass or Fail for an order.

The way to determine these are below:

· Critical defects (totally unacceptable: a user might get harmed, or regulations are not respected) - 0% e.g. plug on an electrical device and it smokes, or a non-welded bar in a bed The product is dangerous

· Major defects (these products would usually not be considered acceptable by the end user) – usually 2.5% e.g. scratches that are noticeable and may prevent the product being sold

· Minor defects (there is some departure from specifications, but most users would not mind it). – usually 4.0% e.g. a small scratch on the bottom of a leg of a bed, or on non-visual piece on an electrical appliance

All Inspection reports generated by the inspection companies listed on Goodada.com will clearly display the AQL standards and show you if the production has failed or passed.

Goodada is a Global inspection company that provides Quality Control Inspections in over 76 Countries We can inspect your Products, Supplier or Cystomer. To see all the countries that we inspect in please visit our Countries Page.

For more information about Finished Goods Inspections, please contact:

Contact Person: Aidan Conaty

Mobile- Messenger (Click to Connect)

Laptop / PC (Click to Connect)

Phone:(Europe/ Rest of the World) +353 1 885 3919 ; (UK) +44.020.3287.2990 ; (North America) +1.518.290.6604

How do I calculate the correct sample size and acceptance value?

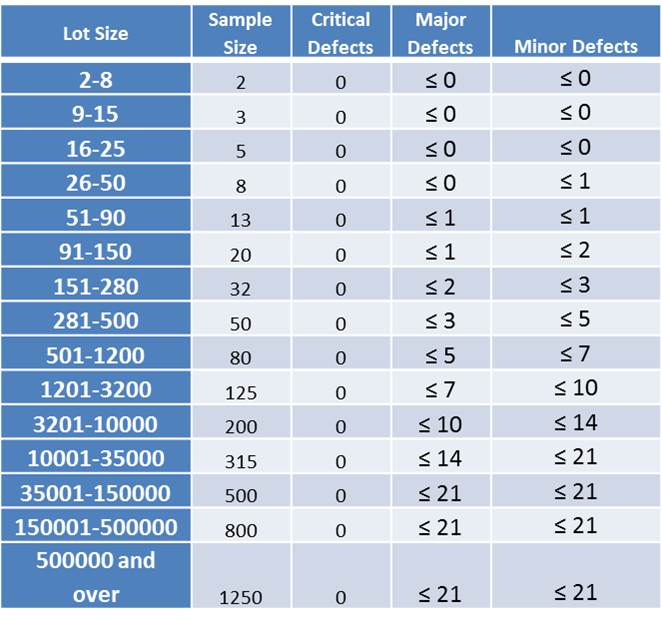

For the majority of products the best suggestion is to use a Standard Level II. If this is the accepted Level then the table below will provide the sample size, critical, major and minor vales (acceptable value) see the page below

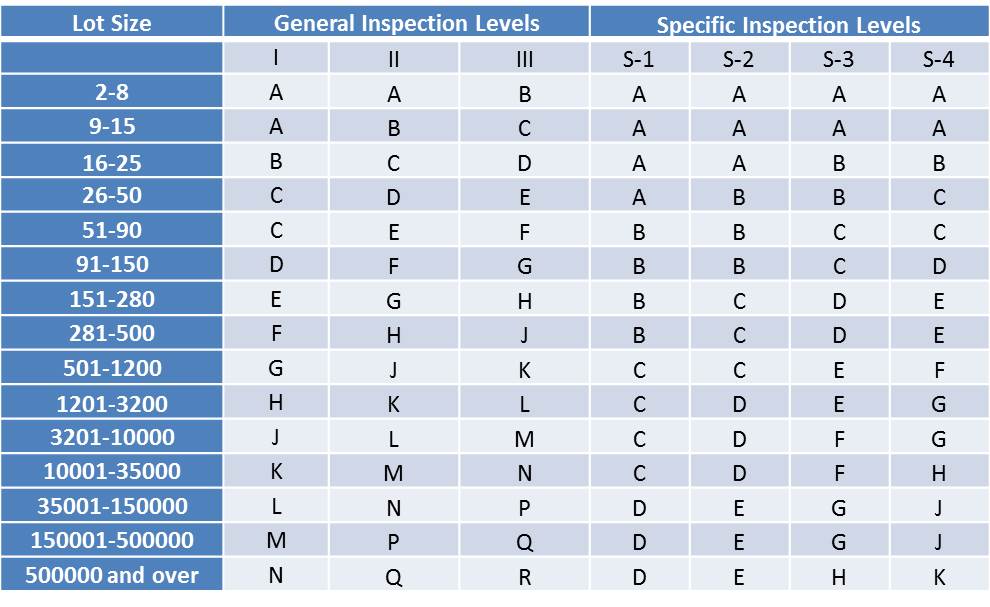

For any non-standard products, or products where the buyer requires a more detailed inspection, please refer to the tables below.

Our inspectors would be delighted to assist you to determine the correct levels, sample size and acceptance numbers

Sample Size Chart – this will allow you to determine the amount or quantity of your sample

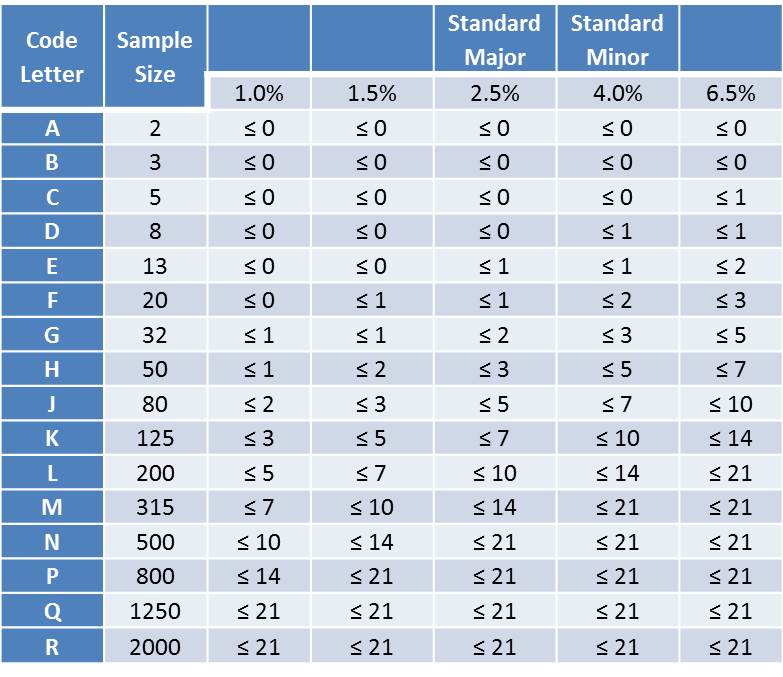

Use the letter identified in the Sample Size Chart to determine the Acceptance Values and Sample Size

Learn More

Types of Inspections

Inspections & Audits

Inspection Countries

Inspection quote

Inspection quote